Craft Your Culinary Arsenal: A Comprehensive Review of Handmade Kitchen Knives

$39.83

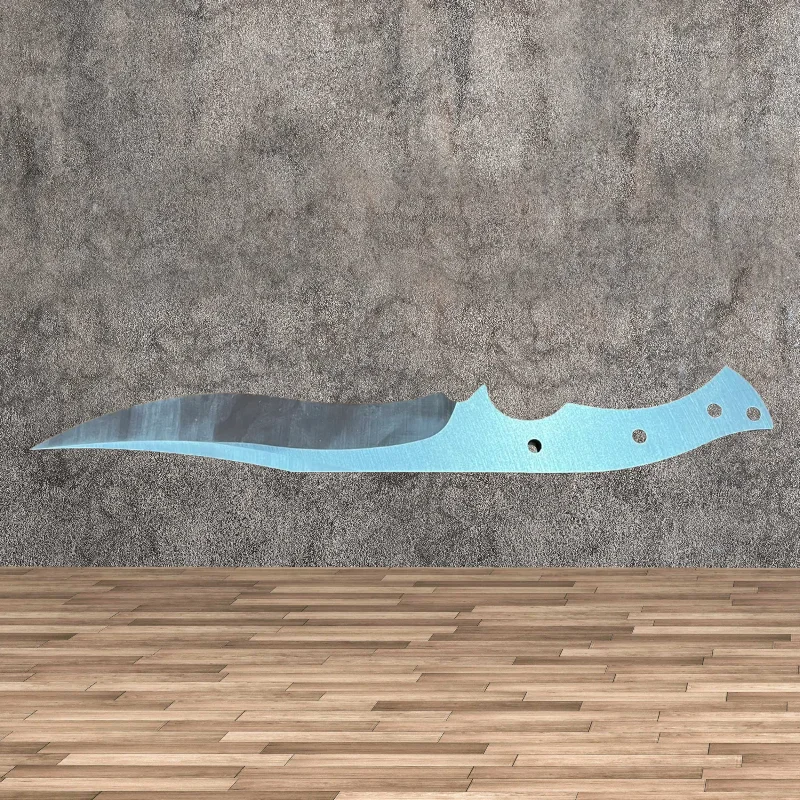

Craft your own culinary masterpiece with our premium handmade kitchen knife DIY blank blade. Forged from authentic Japanese steel, this billet empowers you to create a unique knife that meets your exact specifications. Elevate your culinary skills and impress with every meal.

Handmade Kitchen Knives: The Ultimate DIY Guide to Creating Your Own Culinary Masterpieces

Introduction

In the realm of culinary arts, a sharp and well-crafted knife is an indispensable tool. Whether you’re a seasoned chef or an aspiring home cook, owning a handmade kitchen knife can elevate your cooking experience to unparalleled heights. This comprehensive guide will delve into everything you need to know about crafting your own handmade kitchen knife, from selecting the right materials to mastering the intricate techniques involved.

Chapter 1: Materials and Blade Design

H1: Choosing the Right Blade Steel

The heart of any handmade kitchen knife is the blade, and the choice of steel is paramount. Japanese steel is renowned for its exceptional hardness, edge retention, and corrosion resistance. Here are some popular options:

- Blue Steel (Aogami): Hard and durable, known for its ability to hold an edge for long periods.

- White Steel (Shirogami): Harder than Blue Steel, but more susceptible to corrosion.

- Stainless Steel (AUS-8, VG-10): Corrosion-resistant, but not as hard as Japanese steel.

H2: Blade Shapes and Profiles

The shape and profile of the blade determine its intended use and cutting capabilities. Here are some common types:

- Chef’s Knife: All-purpose knife with a wide, slightly curved blade for chopping, slicing, and dicing.

- Santoku Knife: Japanese knife with a shorter, wider blade than a chef’s knife, ideal for quick tasks like slicing and mincing.

- Paring Knife: Small, nimble knife with a pointed tip for precision work such as peeling and deveining.

- Boning Knife: Flexible blade for removing bones from meat and fish.

- Filleting Knife: Long, thin blade for scaling and filleting fish.

Chapter 2: Forging the Blade

H1: The Forging Process

Forging is the process of shaping the blade from a solid piece of steel. This involves heating the steel to high temperatures and hammering it into the desired form. It requires skill, precision, and an intimate understanding of metallurgy.

H2: Annealing and Hardening

Once the blade is forged, it must be annealed to soften it and relieve internal stresses. The blade is then re-heated and rapidly cooled, a process known as hardening, which increases its hardness and durability.

Chapter 3: Grinding and Sharpening

H1: Grinding the Blade

Grinding is used to refine the blade’s profile, remove excess material, and create the desired bevel. This can be done using a variety of tools, such as bench grinders, belt sanders, and sharpening stones.

H2: Sharpening the Edge

The final step in creating a handmade kitchen knife is sharpening the edge. This is a delicate process that involves using whetstones or honing rods to create a razor-sharp cutting surface.

Chapter 4: Handle Crafting

H1: Choosing Handle Materials

The handle of a handmade kitchen knife is equally important as the blade itself. Common materials include wood, horn, bone, and composite materials. Each material offers its own unique feel, durability, and aesthetic appeal.

H2: Shaping and Fitting the Handle

The handle is shaped and fitted to the blade using a process called mortising. The tang, the part of the blade that extends into the handle, is inserted into a corresponding hole in the handle and secured with glue and/or pins.

Chapter 5: Finishing Touches

H1: Etching and Heat Bluing

After the handle is fitted, the blade can be etched with patterns or designs to enhance its aesthetic appeal. Heat bluing is a process that involves heating the blade to alter its color and create a protective coating.

H2: Finishing the Handle

The handle can be oiled, polished, or coated with a lacquer to protect it from moisture and wear. The final touches complete the creation of a bespoke handmade kitchen knife.

Conclusion

Creating your own handmade kitchen knife is an incredibly rewarding endeavor that combines artistry, craftsmanship, and a profound understanding of culinary tools. By following the step-by-step instructions outlined in this guide, you can forge, grind, sharpen, and finish a culinary masterpiece that will serve as a trusted companion in your kitchen for years to come.